Why Choose GibbsCAM?

GibbsCAM is a cutting-edge CAM system for programming CNC machine tools.

It has the power and flexibility to let you make parts the way you want.

Unique Interface Created For Machinists

GibbsCAM works the way you think. The fully customizable interface makes programming a pleasure.

A Single Application for Programming All Your CNC Machines

GibbsCAM grows with you. Both simple and complex machines are all programmed with one, easy to use interface.

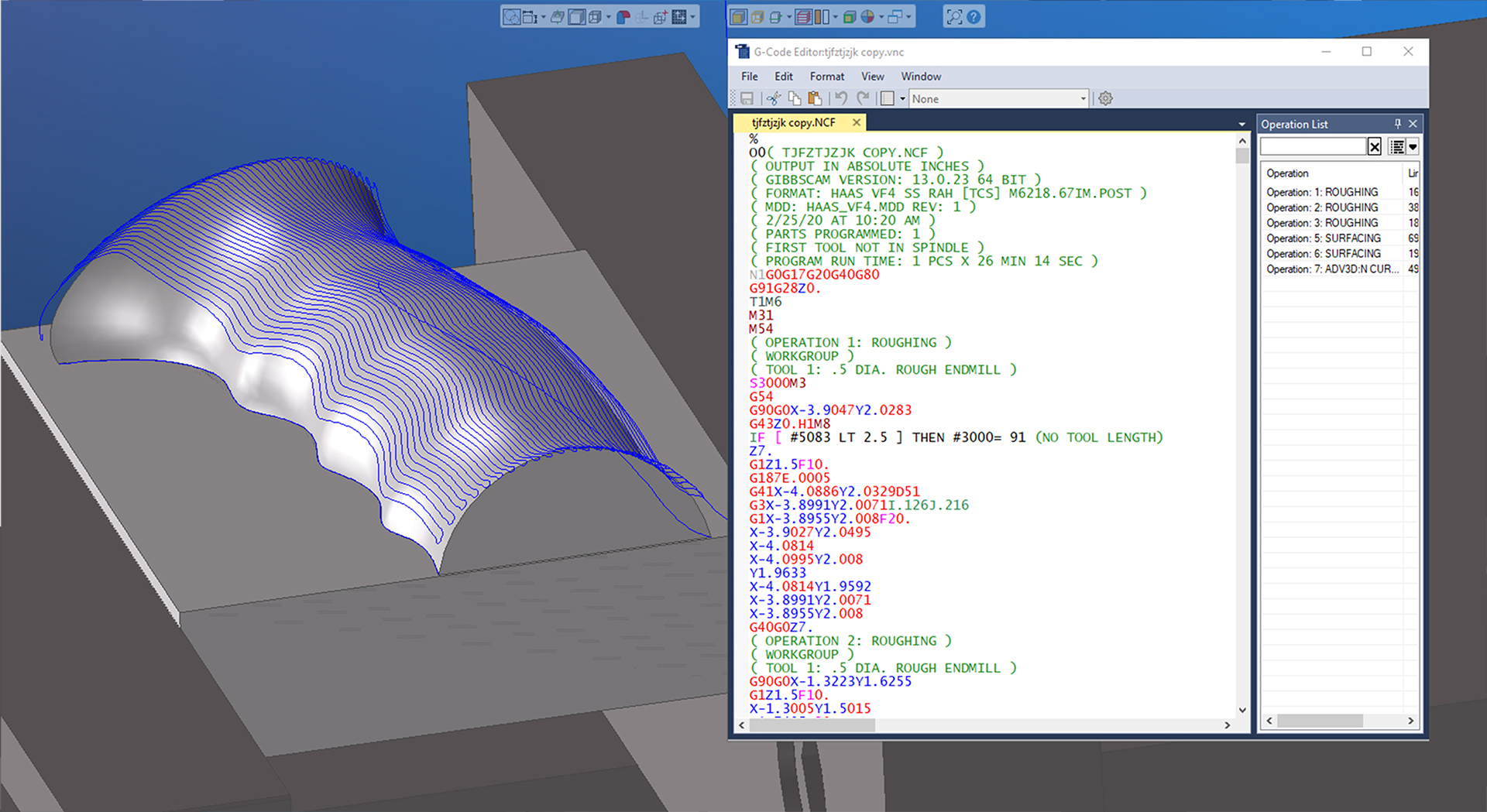

Quality Post Processors for Every CNC Machine

A CAM system is only as good as the posted output. GibbsCAM has the largest library of factory created, error-free post processors on the market.

30-Day Money Back Guarantee

We’re so sure you’ll love it that it comes with a full 30-day money back guarantee!

Computer Aided Manufacturing Software

Full GibbsCAM Mill Demo

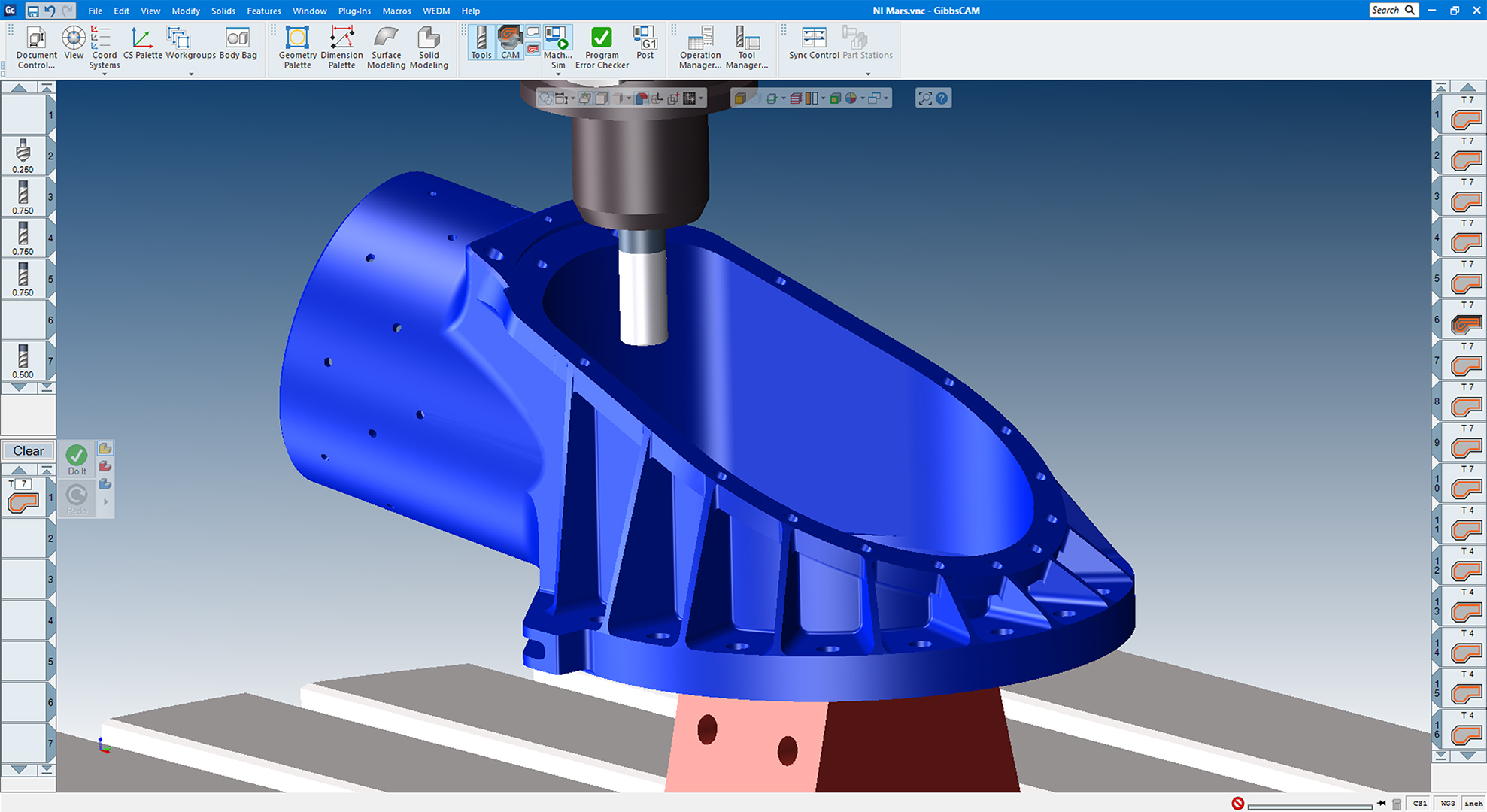

Explore the power of GibbsCAM Milling in this video demonstration. GibbsCAM’s full range of milling options provides you with the power and flexibility to program all your CNC mills with a single program and a single intuitive interface. Packed with powerful toolpath strategies for the most efficient CNC programs for 2 through 5-axis mills, GibbsCAM gives you the freedom to make your parts, your way.

GibbsCAM for 2.5D Solids Milling

GibbsCAM 2.5D Solids Milling delivers an easy to use CNC programming solution for creating, modifying and machining prismatic solid models using a number of different techniques.

GibbsCAM for 3-Axis Milling

GibbsCAM 3-Axis Milling creates smooth, accurate toolpaths for cutting complex shapes using either surfaces, solid models, or any combination of both.

GibbsCAM for Multi-Axis Milling

GibbsCAM Multi-Axis Milling uses state of the art toolpath strategies to generate accurate, reliable G-code for 4 and 5-axis CNC machining centers.

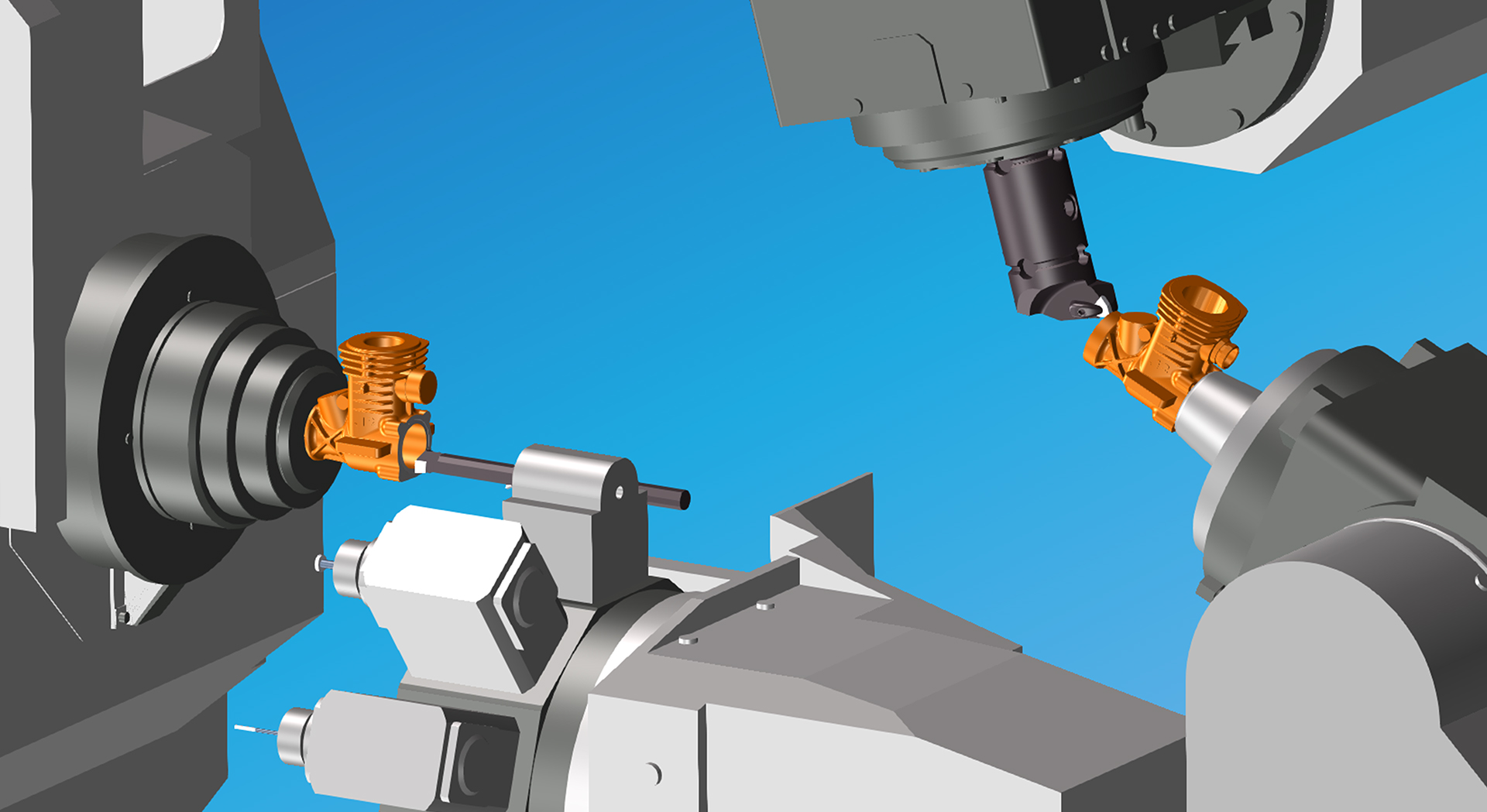

GibbsCAM for Turning and Mill-Turn

GibbsCAM Turning supports full 2-axis turning with a full range of toolpath strategies which makes programming lathes quick, easy, and efficient. In addition, by combining the milling and turning options, you gain mill-turn capability, with support for live tooling.

GibbsCAM for Multi-Task Machining (MTM) and Swiss Machining

GibbsCAM MTM is specifically designed to address the CNC programming requirements of multi-task machine tools, including Swiss-style machining, providing powerful programming tools that are easy to learn and use with the ultimate in flexibility and configurability.

GibbsCAM for Probing

GibbsCAM 14’s new Probing option enables you to graphically complete the entire manufacturing cycle within the GibbsCAM programming interface. In-process probing allows you to take measurements, inspect features, and confirm the accuracy of a part without taking it off the machine. On-machine probing eliminates costly and time-consuming machine downtime and part scrapping.

GibbsCAM for Wire EDM

GibbsCAM Wire EDM option is a powerful, proven, high-end solution to handle all your Wire EDM needs. It includes comprehensive feature recognition and solids machining capabilities, toolpath rendering and simulation, a detailed technology database, and post processors for all major wire EDMs.